Iron & Steel

Aluminium

Copper

Industrial Minerals

Battery Raw Materials

Raw Material Procurement Savings: Measurement and Strategy

Published on

Share Post

Iron & Steel

Aluminium

Copper

Industrial Minerals

Battery Raw Materials

Written bySamir Jaber

Published on

Share Post

Index

Procurement teams across metals and mining operate in one of the most volatile and complex environments in the industrial economy. Raw materials such as nickel, copper, lithium, and ferroalloys move through intense price cycles shaped by supply shocks, energy costs, and shifting trade policies. In this environment, every sourcing decision directly affects competitiveness and cost structure.

Boards and CFOs are acutely aware of this. They increasingly expect procurement performance to be measurable and auditable, not simply reported as anecdotal “savings.” Yet, many organisations still rely on outdated tools and methods that struggle to show where value was actually created.

This is where the conversation around procurement measurement has fundamentally changed. It is no longer enough to show a lower price. What matters is whether procurement truly outperformed the market, managed risk, and delivered resilience.

This article outlines why measurement has become essential, why traditional methods fall short, and how digital infrastructure, like the Metalshub Procurement Solution, enables teams to measure and report results accurately and confidently.

Procurement sits at the intersection of finance, operations, and sustainability. Every purchase decision links directly to margins, compliance, and risk exposure. As a result, procurement leaders face increasing scrutiny from three directions:

In practice, these pressures mean that procurement performance must be expressed in quantifiable, verifiable terms, supported by data rather than assumptions. A buyer who claims success because the new price is 10% lower than last year’s may appear efficient, but if the global index fell 15 % in the same period, the result actually lags market performance.

Procurement measurement, therefore, is not an administrative exercise. It is the foundation of financial integrity and strategic credibility.

Many procurement teams still rely on invoice-to-invoice comparisons or budget variance tracking to demonstrate savings. These methods are simple, but they rarely hold up under audit.

Three limitations stand out:

These weaknesses undermine confidence in reported results. Without a transparent baseline or consistent method, stakeholders cannot distinguish genuine procurement performance from favourable market timing.

To move beyond assumptions, procurement teams need a structured framework that defines how savings are measured and which baselines are used.

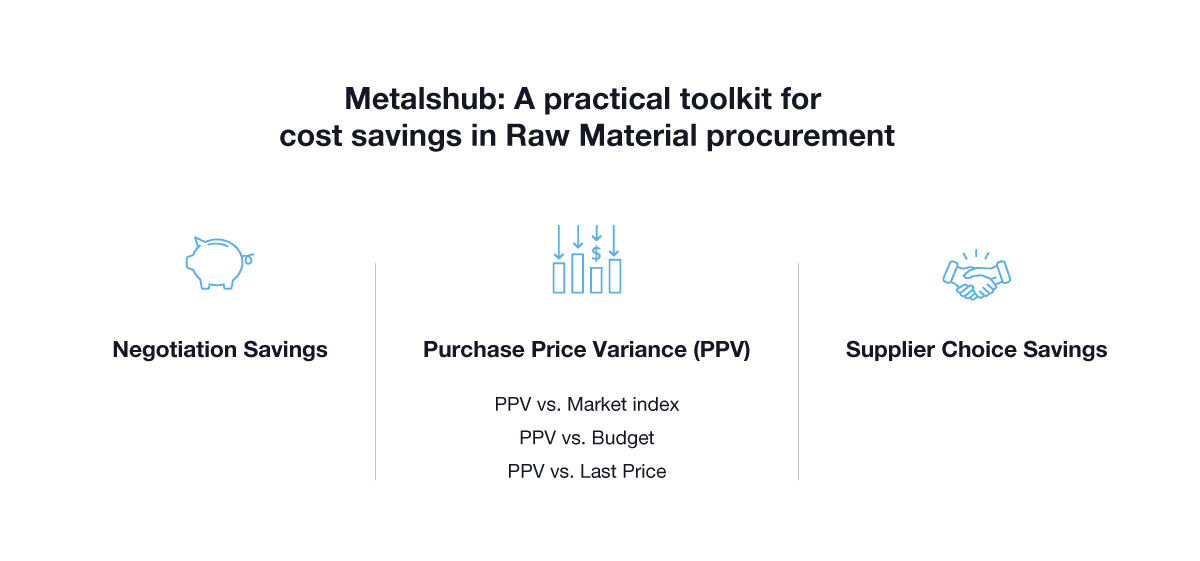

Our whitepaper How to Measure Cost Savings in Raw Material Procurement introduces three core KPIs that form the foundation of this framework:

Each KPI answers a specific question about procurement performance:

The strongest measurement systems combine these metrics to create a balanced view of savings across categories.

Metrics alone are not enough. Their credibility depends on how accurately they are calculated. For example, PPV versus market index is widely regarded as the most reliable indicator of procurement performance because it isolates the procurement effect from the market effect. However, it only works if prices are normalised for comparable terms.

That means adjusting for:

Without these adjustments, even the best KPIs can mislead. Two offers denominated in different currencies or quoted on different delivery terms cannot be compared directly.

This process of normalisation is where traditional spreadsheets reach their limits. It is time-consuming, prone to error, and difficult to audit. For most teams, the challenge is not defining KPIs but collecting, normalising, and maintaining reliable data to support them. That is where a digital platform like Metalshub can be of significant value for a procurement team; and it is not purely cost savings.

While savings remain the most visible indicator of procurement impact, they are only part of the story. Mature organisations track a broader set of KPIs to ensure procurement is competitive, compliant, and resilient.

These include:

Together, these KPIs form a procurement scorecard that connects sourcing activity to business performance. They also demonstrate to boards and auditors that procurement is managed with the same discipline as finance and production.

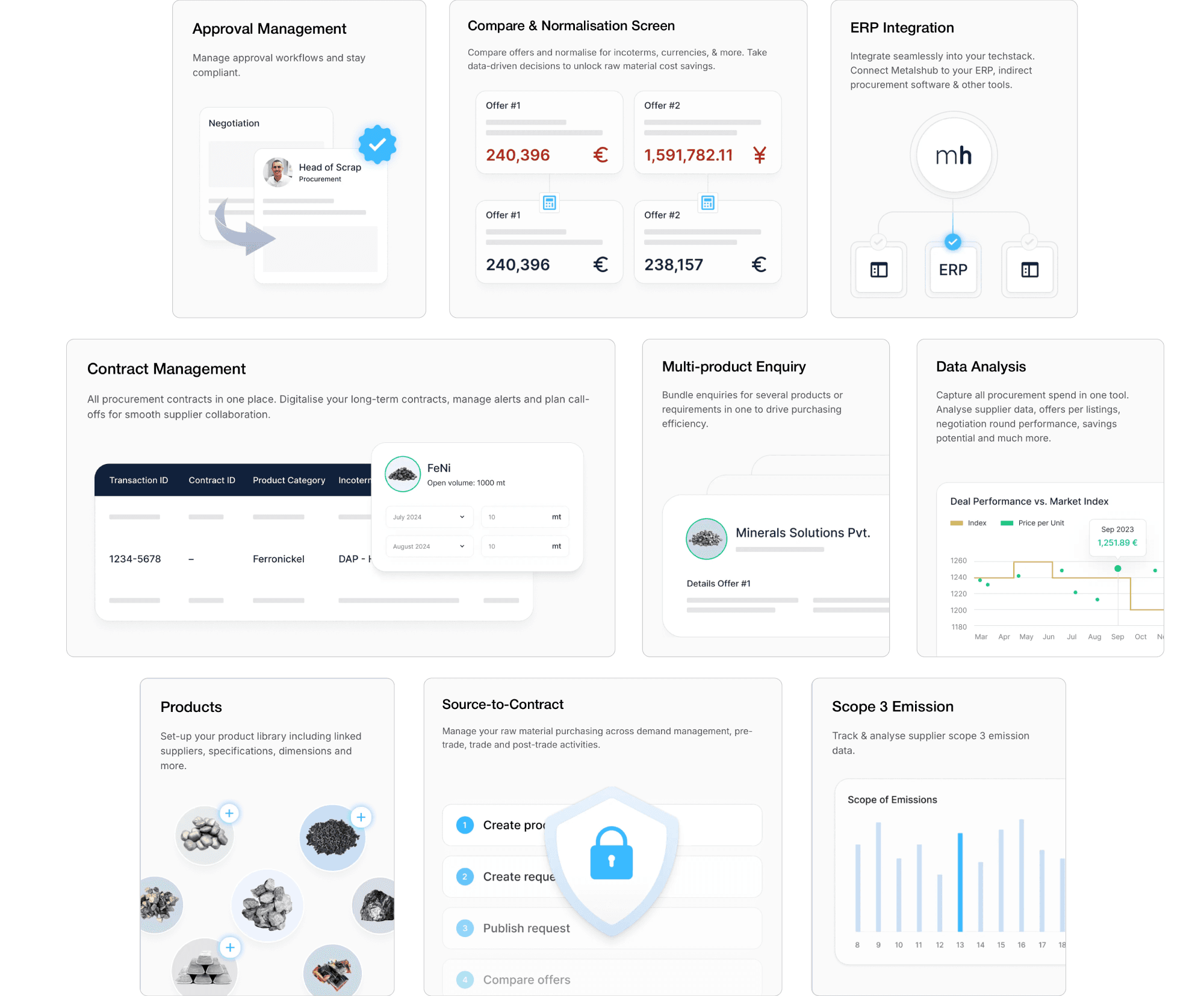

Turning this measurement framework into practice requires a robust digital foundation. Traditional tools like spreadsheets or manual reports cannot provide the accuracy, consistency, or traceability needed under modern governance standards.

This is where Metalshub plays a decisive role.

Metalshub’s digital procurement platform embeds data capture and measurement directly into the sourcing workflow. Every RFQ, offer, negotiation round, and award is stored in structured data, creating a complete and auditable record.

Key features that simplify procurement measurement include:

By capturing structured data at every step, Metalshub eliminates the manual consolidation and subjective adjustments that often distort procurement reporting. Measurement becomes an integrated outcome of the sourcing process rather than an additional administrative task.

The benefits of leveraging the Metalshub digital platform for accurate procurement measurement extend beyond internal reporting.

Most importantly, teams that measure performance effectively can identify where savings are genuine, where they result from market movements, and where new opportunities for improvement exist. This transforms procurement from a transactional function into a strategic value driver.

Procurement’s role in metals and mining is evolving fast. The expectation is no longer to “buy well” but to prove how and where value is created. With complex supply chains, volatile markets, and rising transparency requirements, the proof must rest on data, not intuition.

Digital platforms like Metalshub provide the structure to make this possible. By embedding measurement directly into procurement workflows, it ensures that every sourcing decision can be analysed, benchmarked, and reported with confidence.

How to Measure Cost Savings in Raw Material Procurement provides the complete practical toolkit, including detailed KPI definitions, formulas, and real-world examples.

👉 Download the whitepaper to learn how to measure, benchmark, and report procurement savings with precision and credibility.

Newsletter

insights

February 02, 2026

Read more

January 29, 2026

Read more

January 22, 2026

Read more